Things I’ve 3D Printed (Part #2: With a Bit of Wiring)

Some of the coolest prints don’t just sit still. Here are a few things I’ve made that light up, spin, or run on a bit of wiring and a lot of curiosity.

Not everything I print just sits on a shelf. Some of my favorite projects involve a little wiring, a few lines of code, and just enough troubleshooting to make me wonder why I started - before reminding me exactly why I love this stuff.

This post is about the prints that move, light up, or plug in - nothing fancy, just a bit of wiring and a lot of curiosity.

Custom Lamps – When Printing Meets Electronics

I’ve always liked combining 3D printing with a bit of circuitry, especially when the result can sit on a shelf and glow quietly. These lamps are simple projects, but they’re some of my favorites.

One is a jellyfish lamp with translucent filament for the body and tentacles, lit from below with soft blue LEDs. It looks surprisingly alive at night - like it’s floating mid-air beside my keyboard. I designed and shared it on Thingiverse here - it runs on 5V and plugs in via MicroUSB.

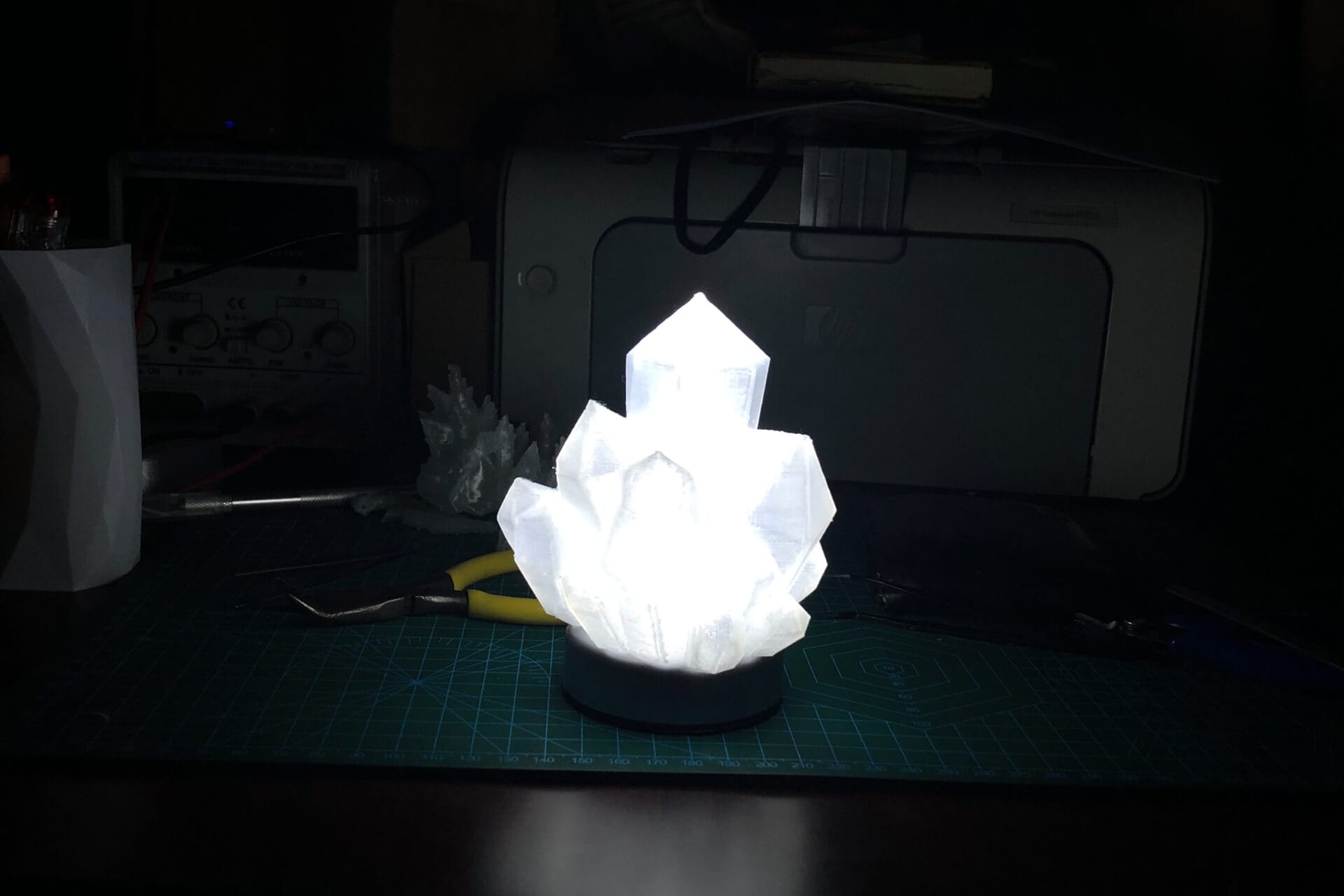

Another is a crystal cluster that glows like a magic prop from a video game. It’s just white PLA and a diffused LED, but when you turn it on in a dark room, it becomes pure ambiance. You can find that one here - powered by 12V and perfect for mood lighting.

These weren’t full-on electronics builds - just quick weekend prints enhanced with USB-powered light modules or LED bases. But those small touches made them way more personal and satisfying.

You don’t have to go full Arduino to make a print feel alive. Sometimes a good design and a cheap light are enough.

Watch Winder – Custom-Built, Arduino-Controlled

This one’s for the tinkerers.

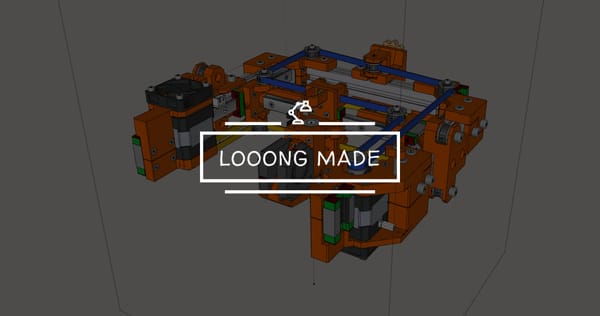

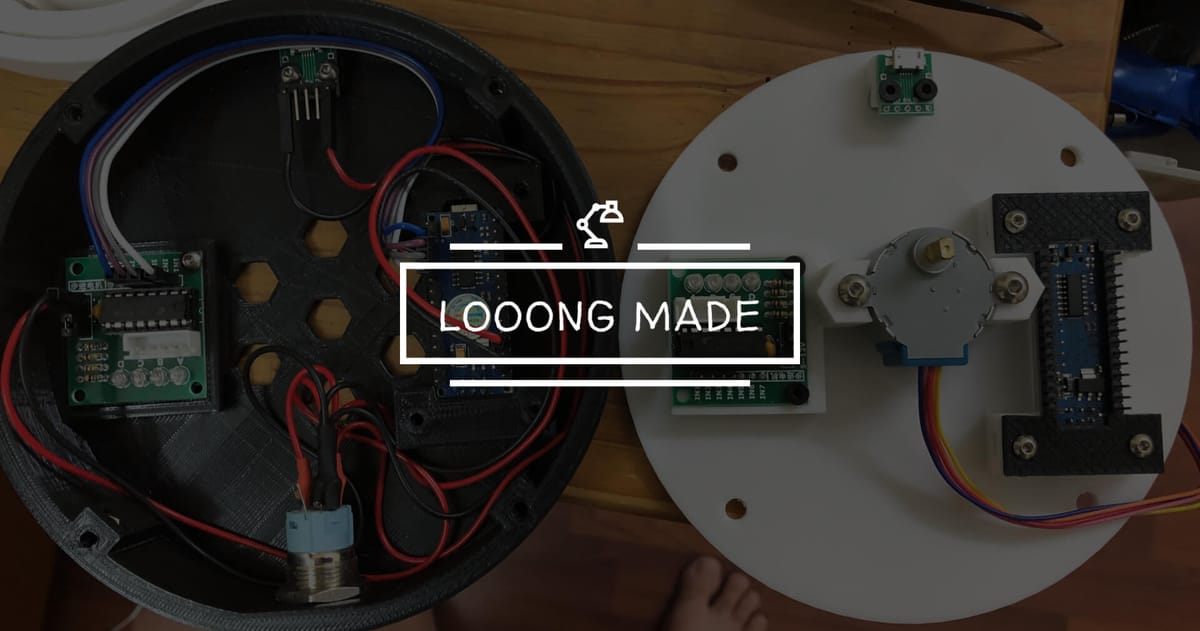

I needed a watch winder - something to keep an automatic watch moving when it’s not being worn - so I found a basic design online and customized it. I added bearings for smoother rotation, used a stepper motor for quiet, precise movement, and wired the whole thing to an Arduino board to control the timing and direction.

The first working version - rough but functional. Powered by an Arduino and stepper motor, with a basic frame and minimal tuning.

The print was only the beginning. The real work was getting the motor tuned and the enclosure just right so the movement stayed smooth and quiet. It took a few test runs, a couple wobbly starts, and some code tweaks - but now it just quietly does its job.

Upgraded with smoother bearings, better fit, and cleaner motion. Still Arduino-powered, now quiet enough to run on my desk all day.

This was one of those builds where 3D printing wasn’t the solution — it was just the starting point. The rest came from iterating and integrating until it actually worked. And now? It feels like a gadget I’d proudly buy… except I didn’t have to.

Closing Thoughts: Printing Isn’t Just Plastic

A 3D printer doesn’t have to stop at shapes. Once you realize you can mix in wires, lights, motors, magnets, sensors, and a bit of imagination - the whole thing starts to feel like magic.

Even small projects can teach you a lot. And honestly, the reward isn’t the gadget itself - it’s seeing something you built quietly spinning, lighting up, or just doing its thing in the background.