Little Cube - My Lockdown CoreXY Build

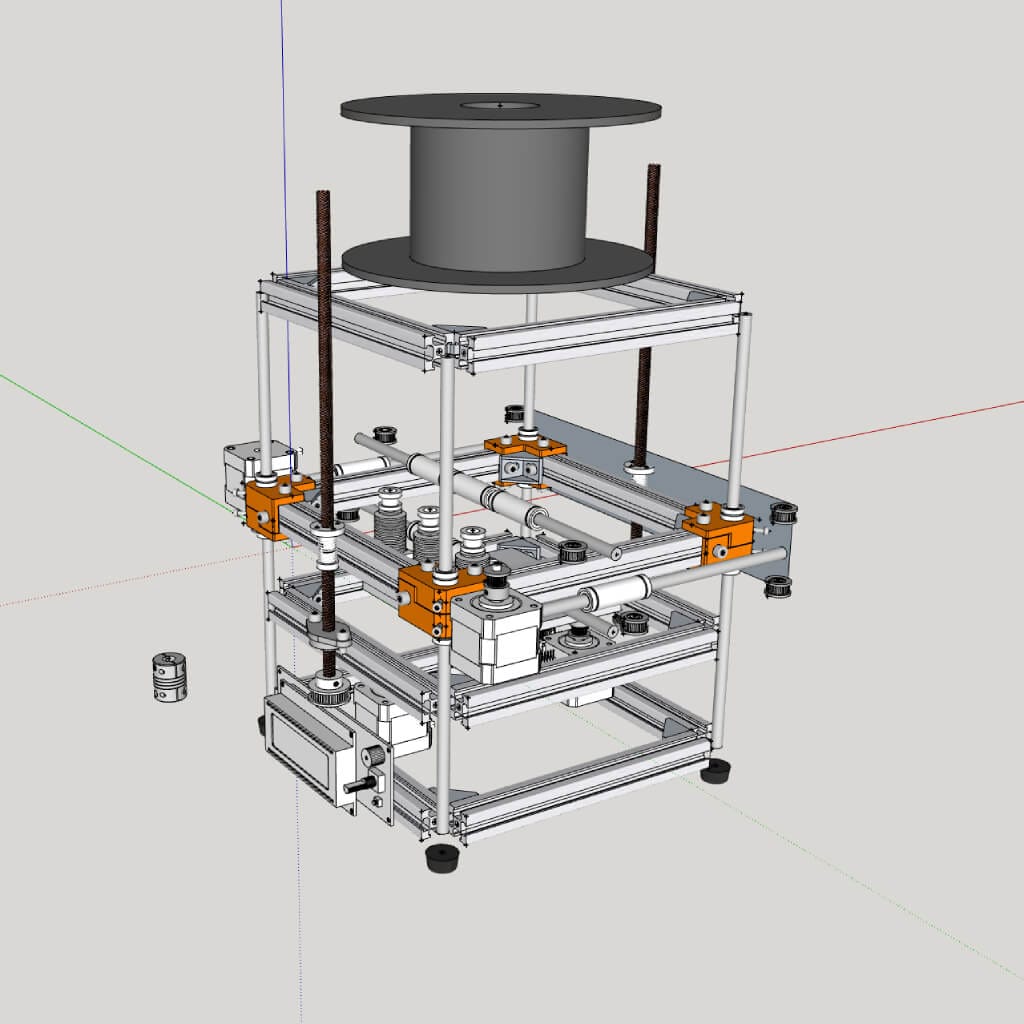

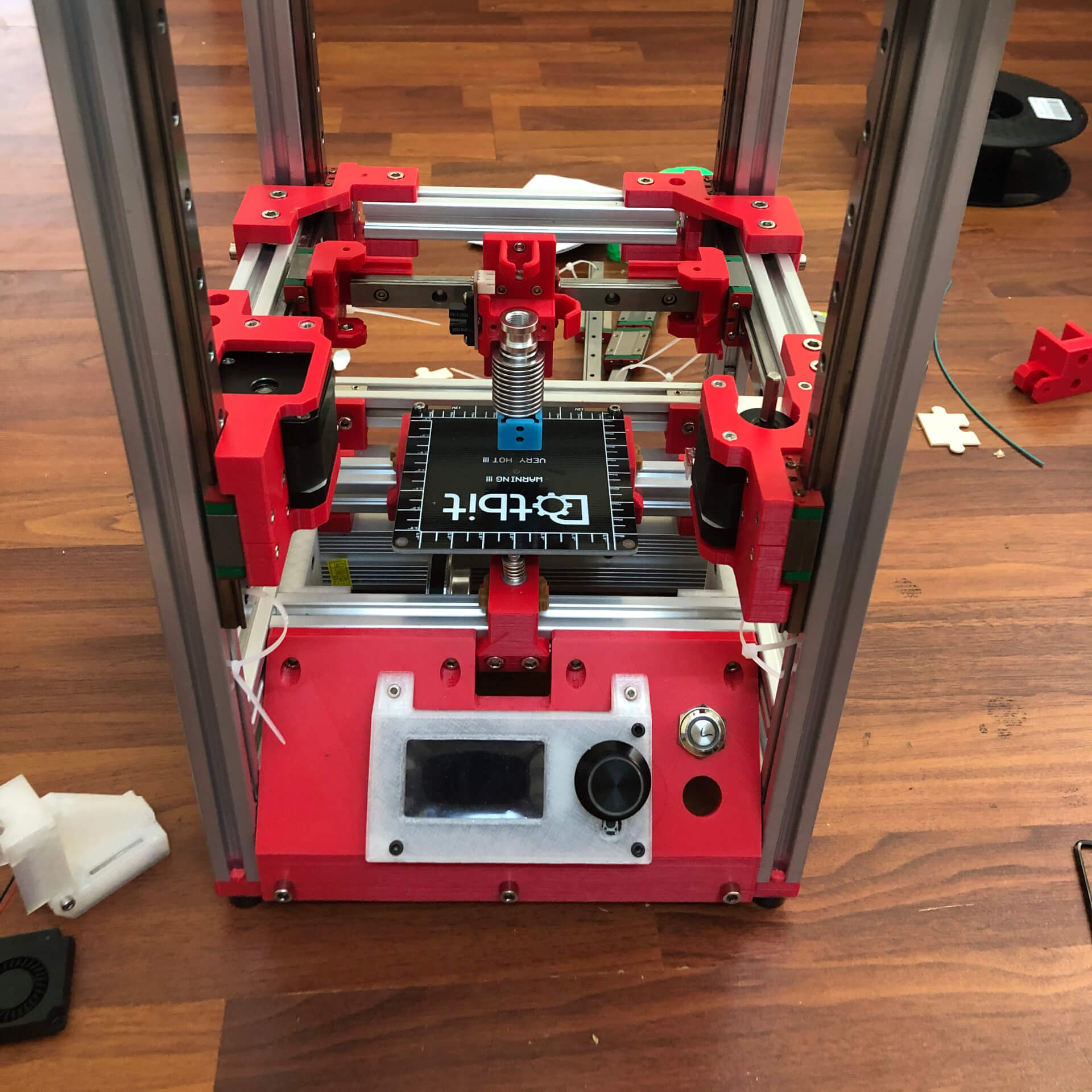

Five months of lockdown. One compact CoreXY printer. The story of building Little Cube - a 100mm³ fixed-bed printer designed for portability and built for fun.

I was looking at my two CoreXY printers one day and something clicked.

The 300x300mm HEVO I'd built from a "Good Luck" kit. A larger custom build made from leftover parts. Both solid machines. Both worked well.

But 90% of what I was printing fit in a 100x100x100mm cube.

Large beds take 5 minutes to heat up. The printers are heavy - hard to move around when I need to repair or upgrade parts. They need dedicated space - you can't just find a spot for them. And I couldn't travel with them. When I wanted to demo something at the office? Not happening.

Then lockdown happened. Time opened up. And I had an idea.

The Third Build

This was my third printer. I love building printers - there's something about designing and assembling your own machine that just works for me.

The HEVO taught me CoreXY motion and connected me to RepRap - that incredible open-source community where everyone shares designs and helps each other build. I started contributing too: parts on Thingiverse, troubleshooting help, pull requests to Marlin.

The larger build taught me to work with whatever I had and think big.

Now I wanted to go small. Intentionally small.

What I Wanted

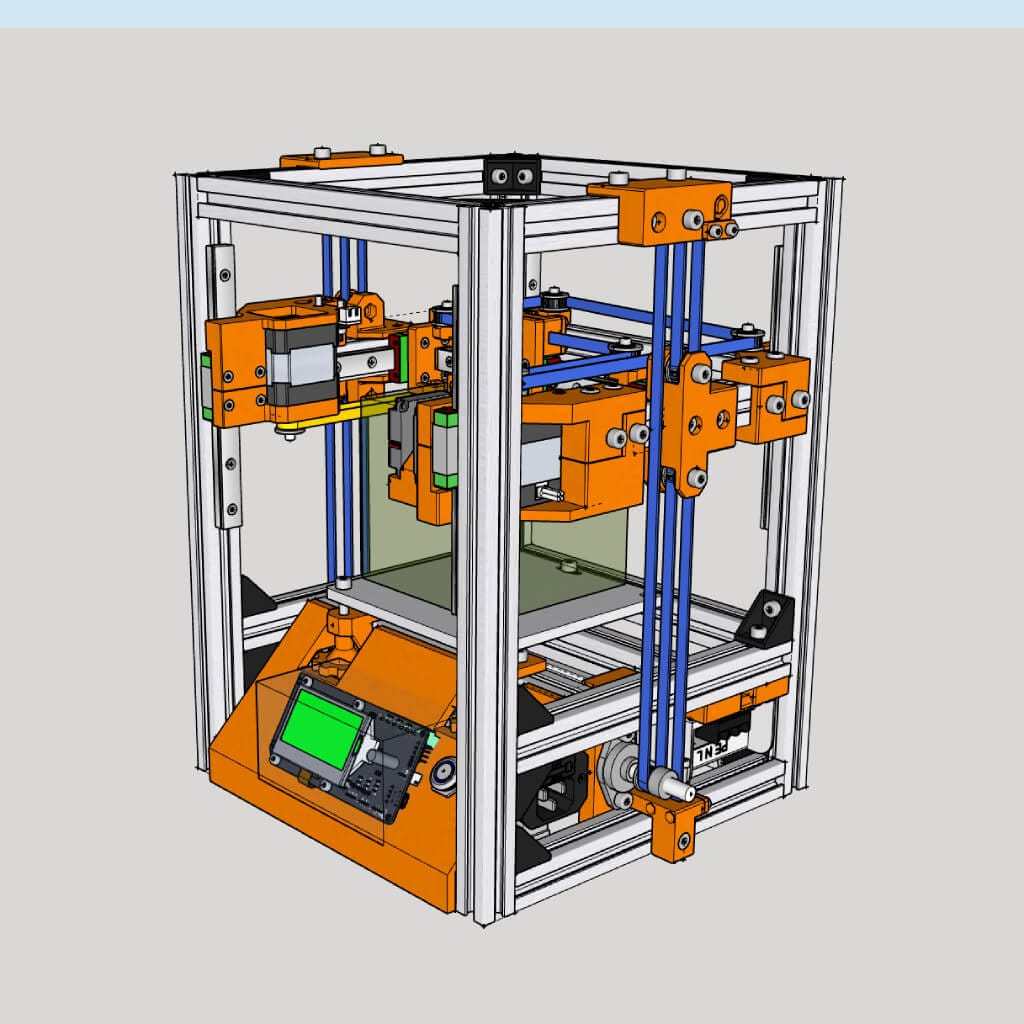

Space optimization. Footprint just slightly larger than a filament spool. No more massive printers eating up workspace.

Less tuning hassle. Fixed bed that stays put. Smaller print surface meant less leveling drama.

Portable. Something I could carry to the office for demos and bring back home without help.

Belt-driven Z. I wanted to try a belt system instead of lead screws - figuring out the right ratio would be part of the challenge.

Compact hotend. Just 30mm wide - in a 100mm printer, every millimeter counts.

100x100x100mm volume. Perfect for 90% of my prints.

And honestly? I wanted it to be fun. Over-engineered in a good way.

Five Months

January 18th, 2020 to June 15th, 2020.

Designed in SketchUp. Printed parts on my existing printers - about 1kg of PLA+ for all the structural pieces. 2020 extrusions for the frame. MGN12 rails for smooth motion. CoreXY belts I'd learned to trust.

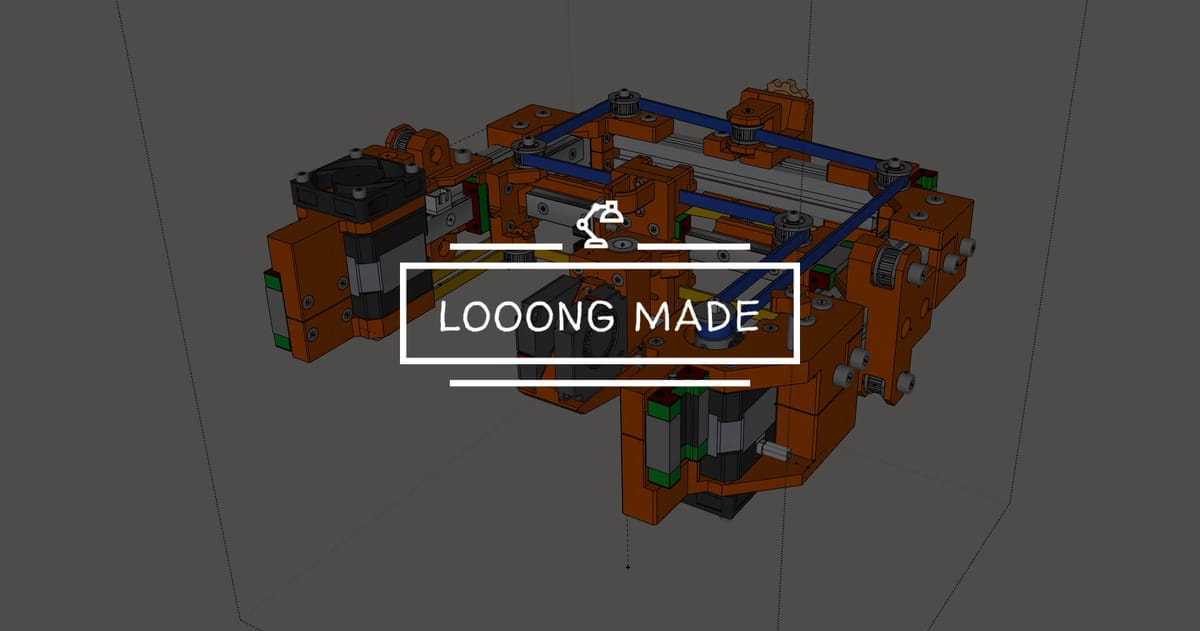

The Z-axis was the interesting bit - belt-driven with a pulley arrangement giving 1:10 mechanical advantage. Smooth. Precise. Different from anything I'd built before.

Not A Kit

When I say "over-engineered," I mean it takes commitment.

You need tools. Allen keys, files, crimper, soldering station. You need to source cables, terminals, hardware, belts, extrusions cut to length. I had all of this already stocked - one of the reasons I could build during lockdown when everything was shut down.

And you need another printer to print the parts for this one.

There's a GitHub repo. A jig.stl file. No step-by-step instructions.

It's a project, not a kit.

Why

Because I wanted to.

Because I love building printers.

Because lockdown gave me time and I had an idea worth trying.

The best projects aren't always the most practical ones. They're the ones that teach you something and make you better at what you do.

Five months from idea to first print - Little Cube doing what it was built for