The 3 Most Popular FDM Printer Types

A breakdown of the 3 most popular FDM printer types - Cartesian, CoreXY, and Delta - with pros, cons, and practical advice.

When I first got into 3D printing, I thought all FDM printers were basically the same - just boxes that push plastic around. I didn’t realize how much the movement system, bed style, and even the frame design would affect the results I got (and how much time I spent tuning them).

My first printer wasn’t even a typical beginner machine - it was a HEVO variant (a community-driven CoreXY design). It looked intimidating at first, but it also taught me a lot about structure, motion, and how different every FDM setup can be.

If you’re thinking about getting a printer - or just want to understand why one model looks so different from another - this breakdown will help. Let’s explore the three most common FDM printer types and what each is best suited for.

1. Cartesian Printers

Simple, Familiar, and Beginner-Friendly

Most people’s first printer is some form of Cartesian design. The name comes from the classic X/Y/Z axis movement - each axis is controlled independently.

Bed Movement:

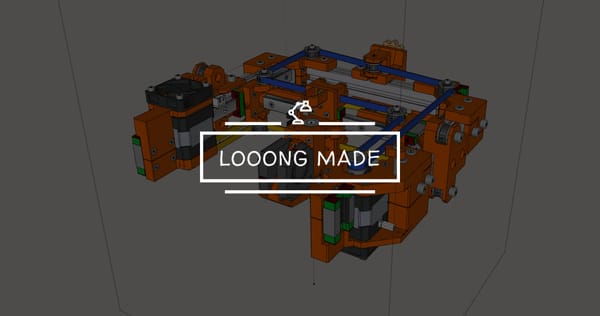

- Bed-Slinger (e.g., Prusa Mini): The bed moves forward and backward along the Y-axis.

- Z-lift (e.g., Prusa XL): The bed drops down gradually as layers build.

- Some rare Cartesian setups use a stationary bed, but that’s uncommon.

Operation:

These printers are mechanically simple and easy to understand. That also makes them great for modding or fixing when things go wrong. Most models require manual or assisted bed leveling, which can get annoying over time - especially if the bed moves along Y.

Frame Style:

While many Cartesian printers use an open-frame design, some higher-end or modded builds use a rigid box frame. This keeps all movement inside the structure, improving motion accuracy and making it easier to add an enclosure - a big win if you want to print with ABS or similar materials.

In my opinion, open-frame bedslingers are the best choice for simple, low-maintenance setups. Their minimal design makes them easy to build, operate, and troubleshoot. If your goal is to just print - not tinker for weeks - this style is hard to beat.

Best For:

- Beginners

- DIY modders

- Budget-conscious makers

- People who want a minimal, clean setup

2. CoreXY Printers

Fast, Rigid, and Built for Performance

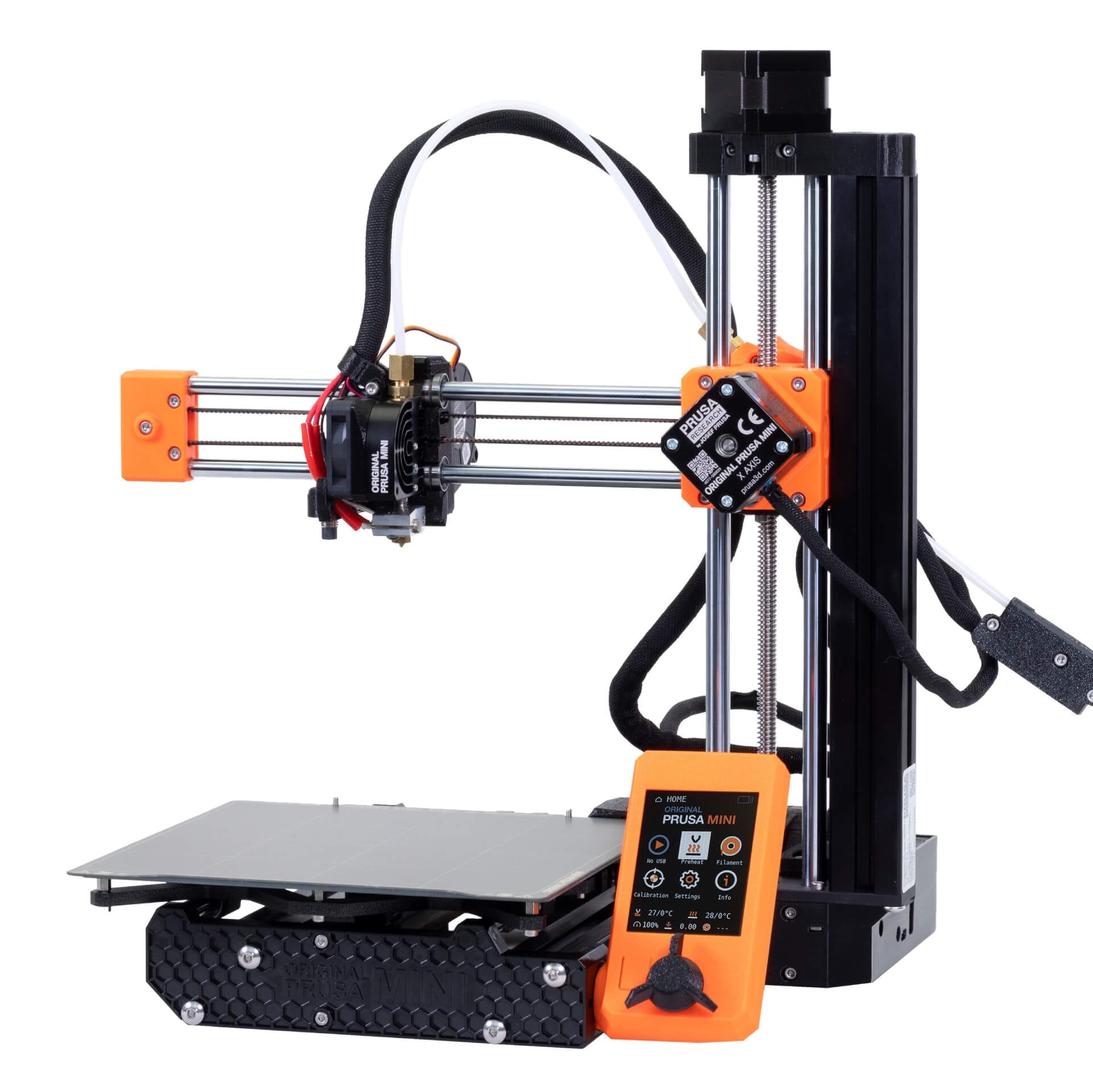

CoreXY printers use a unique belt system where two stepper motors work together to move the head in the X and Y directions. The result is fast, fluid motion that keeps the print head light and nimble.

Bed Movement:

- Most CoreXY printers use a Z-lift bed - it moves down slowly as each layer is printed.

- Some designs (like Voron V2) go even further, keeping the bed completely stationary and raising the entire gantry instead.

Operation:

These printers are precision machines, but they come with complexity. Belt tensioning matters. Frame alignment matters. But once it’s dialed in, CoreXY systems can print faster and more cleanly than most Cartesian setups.

Frame Style:

CoreXY printers almost always feature a rigid, cube-style frame. This boxy design isn’t just aesthetic - it keeps the structure solid and allows all movement to happen within the enclosure.

From my experience, rigid box-frame designs are the best platform for large-volume printing, especially in controlled environments. Their enclosed motion system makes them ideal for upgrades - like enclosures, multi-head setups, even lasers or vent systems. The frame becomes your backbone for long-term expansion.

Best For:

- Speed-focused users

- Prosumer/professional setups

- Multi-functional mods

- Makers building a workshop centerpiece

3. Delta Printers

Tall, Fast, and Fun (If You Like a Challenge)

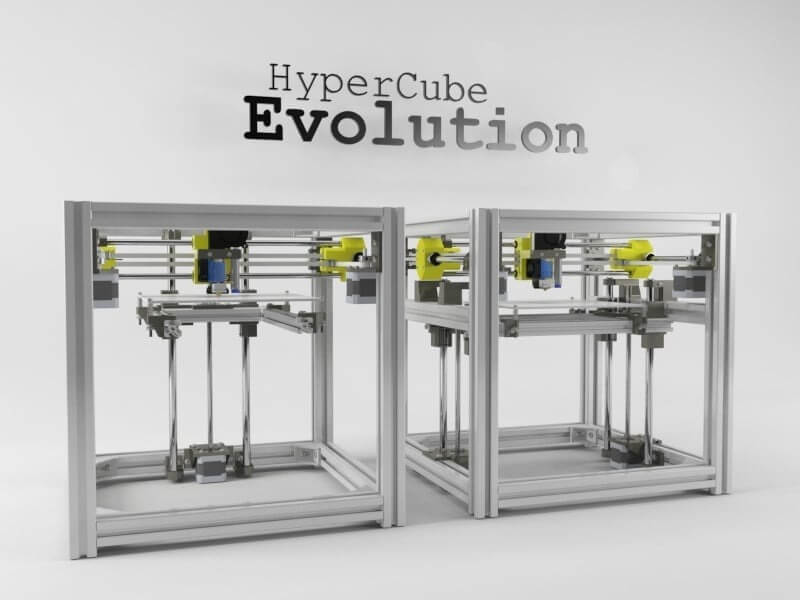

Delta printers look like something out of science fiction - three vertical arms working in sync to move a central print head. Their motion system is completely different from Cartesian or CoreXY designs, relying on mathematical coordination rather than separate axes.

Bed Movement:

The bed is always stationary. Only the head moves, suspended on three arms that adjust together.

Operation:

Deltas are fast and smooth, especially for tall or cylindrical prints. They’re also surprisingly quiet. But they can be harder to tune. Bed leveling and firmware configuration tend to be more advanced - though many models now include auto-calibration.

That said, in my opinion, speed isn’t everything in FDM. The material needs time to cool and form shape - pushing too fast can lead to ringing, poor adhesion, or sagging details. So even though Deltas can print quickly, dialing it back often gives better results.

Personally, I’ve never clicked with Delta printers. My OCD kicks in hard when axes aren’t parallel, and Delta’s geometry feels too abstract for me to enjoy. I don’t have much hands-on experience with them, mostly because the motion system doesn’t match my brain (or my build style).

Frame Style:

The frame is usually tall and triangular. It’s stable and compact, but doesn’t easily accommodate enclosures unless specifically designed for it.

Best For:

- Advanced users

- Tall prints

- People who enjoy tinkering and solving weird geometry problems

Final Thoughts

There’s No “Best” - Only What’s Best for You

Each printer type has its strengths and quirks. If you’re starting out and want something affordable and simple to learn on, go with a Cartesian. If you’re ready to print fast and value precision, CoreXY is hard to beat. If you’re curious and want to push your skills, give Delta a try - just be ready to learn a bit of math.

Understanding these styles helped me form clear opinions about what I wanted in a printer - and eventually, it influenced how I designed one of my own. That journey’s still ongoing, and I’ll share more about it in a future post.